Sheet Extrusion Process

Extrusion is the primary process in the manufacturing of rigid plastic cups and containers. It is the process of converting the plastic granules into a sheet in order to make the end product (plastic cups and containers).

- The plant has a sheet processing capacity of 4 tonnes per day

- Can process both Polystyrene and Polypropylene

- Can process a sheet of up to 2 layers

- There is an automated feeder system for the granules, thereby reducing manual intervention and resulting in high quality output.

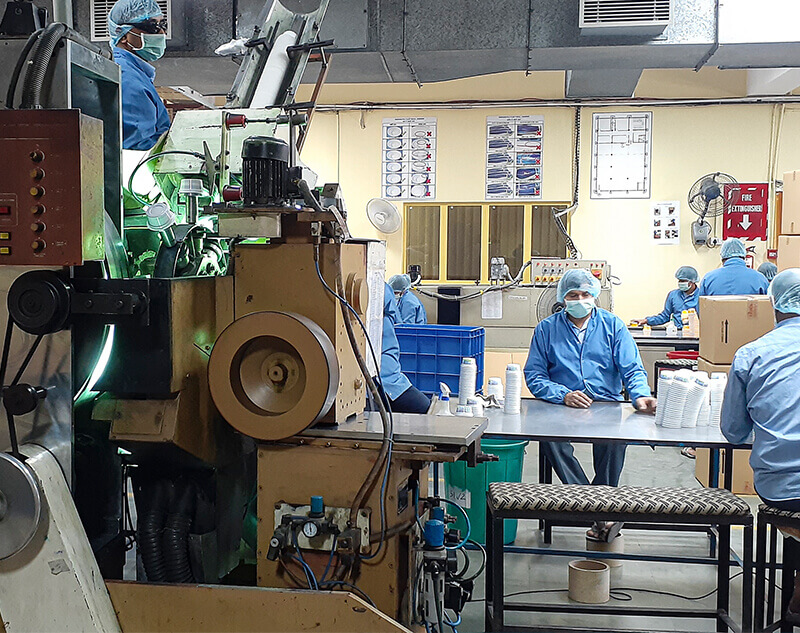

Thermoforming Process

The plastic sheet made in the extrusion process is heated to a pliable temperature in the thermoforming machine and then passed through a mold and cavity set of desired shape and size to convert it into cups and containers.

- Can manufacture up to 0.75 million cups per day

- Can process both Polystyrene and Polypropylene sheets

- Have the ability to thermoform cups and containers of various shapes and sizes ranging from 45g - 1kg.

- Have the know-how to innovate and design new cup shapes at our Research, Development and Innovation hub.

Cup/Container Visual Enhancement Techniques

Decorating the cups and containers is a vital activity in the cup manufacturing and packaging process. The look of the cup impacts the attractiveness of the cup which can directly influence consumer choice. At VPP we understand this and offer our customers a choice between shrink sleeving and printing.

Shrink Sleeving Process

Printed shrink sleeves have gained prominence as a leading packaging solution. It is an excellent way of providing shelf appeal to a product as the full area is available for decorating the cup/container. The shrink sleeve is applied using heat application.

- Can process up to 0.45 million shrink sleeves per day on cups & containers

- Have the capability of auto loading cups, automatic sleeve applicator and cup counting and stacking to ensure minimum human intervention in the sleeving process.

- Sleeves are customised to customer specifications and requirements.

- Sleeve design are more appealing.

Printing Process

At VPP the other cup/container decoration option that is offered to our Customers is Dry Offset Printing. The plant has dry off-set printing machines, which can be used for printing of up to 6 colours.

- Can print up to 0.4 million cups per day

- The printing inks used are food grade and completely safe.

- Inks options for printing are ultraviolet/ non-ultraviolet

Recyling Process

At VPP, we undertake 100% recycling of the plastic waste that is generated in-house at the Plant. The plastic waste collected from all the processes is fed to the in-house Plastic Grinding Unit. Through this process, the plastic sheet and cups/containers are cut down to the desirable size where they can be re-used in the Extrusion Process as a mix with the virgin raw material plastic granules.

Design & Development Centre

VPP has a Design & Development Centre located in New Delhi, where we actively work towards making new shapes, designs and sizes of the cups/containers. We have actively partnered with our clients in the past to launch new products in the Indian market.